Truth #1: The lifespan of UV optics varies.

People often ask how long the UV optics last. It is true the answer could be 8,000 hours or more. However, this is very misleading. UV light gradually loses power over time. The patented technology is based largely on the power of these optics. Yes, the optics will stay lit for 8,000 hours or more, but the machines become weaker and weaker the longer they run. Jobs that used to take three days to complete may now take four or more. In this industry, when dealing with moderate to severe odours, it is recommended that optics be replaced after the hour meter shows 4,000 hours of usage.

Truth #2: Coverage area varies on a job-to-job basis depending on several factors.

What size area will one machine cover? Since every odour project is unique, there are always variables to consider such as the layout of the structure, the number of contents on site, the severity of the odour, and how quickly the odour should be eliminated.

A general rule of thumb is that one machine will cover 1,000 – 1,500 square feet with ceiling height up to about twenty feet or so. Some experts have indicated a machine will treat “up to” 40,000 cubic feet or more. Could it? Perhaps, but treatment would take a long time with the machine having to be moved around continuously.

Truth #3: Ozone is generally faster, but unlike ozone, crews can keep working while hydroxyl generators run eliminating interruption and down time.

Lastly, people usually want to know how long it takes hydroxyls to work compared to ozone. Scientifically, hydroxyls are one million times more reactive than ozone. This means that they will disassemble a much larger range of odours and VOCs. However, the time it takes to do this is determined by the concentration of oxidants used. The average ozone generator compared to the average hydroxyl generator will be faster. For example, if it took the ozone generator 24 hours to work, the hydroxyl generator will take 36 hours.

You can let adjusters know that the hydroxyl generator can be running while the physical work is being done.. So, the job is now streamlined and the odour will be gone sooner. This can now decrease or eliminate the need for ALE or business interruption. It is also important to remind them that, unlike ozone, hydroxyls will not damage sensitive materials and can be run while the treatment space is still drying.

This should address the more frequent questions. We’re always available to answer more questions and provide training classes for interested parties.

Final Comments

There are three levels that one can take in using hydroxyls in odour remediation. These are:

- Aggressive which has people working with the hydroxyls running in the same work area;

- Moderate which has people working with the hydroxyl generators in a limited capacity; and

- Conservative where no one is working in the same area as a hydroxyl generator.

The Conservative approach is what we have taken at Alberta Fire and Flood. In this way, we can be assured to eliminate all the confusion around the interaction between hydroxyls and people.

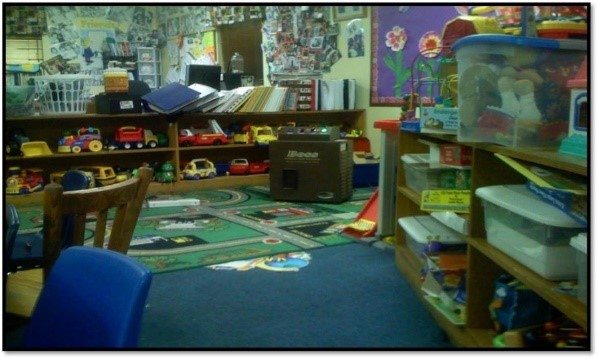

Everything you can see in this daycare was effectively deodorized of smoke odour with hydroxyls.

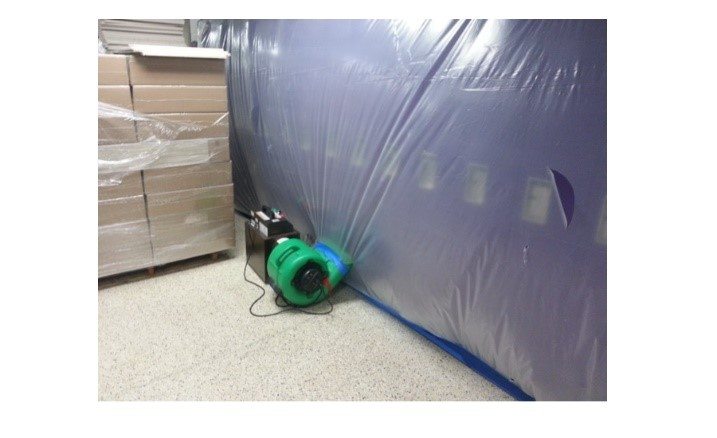

Containment was built over the student lockers, then hydroxyls were injected. Had that deodorization techniques not been available all the lockers would have to be removed.

Leave A Comment

You must be logged in to post a comment.